Review Article - (2025) Volume 2, Issue 1

Recyclability of Broken Pile Head Concrete in Structural Use

2Professor, Department of Civil Engineering, BUET, Bangladesh

Received Date: Jan 20, 2025 / Accepted Date: Mar 10, 2025 / Published Date: Mar 28, 2025

Abstract

To improve sustainability, the use of recycled concrete aggregate in the construction industry has increased globally. Urban areas are experiencing a critical shortage of natural aggregate for concrete production. Recycling construction and demolition waste, generating recycled aggregates and using them as an alternative material, could be a solution. This paper presents the recyclability of broken pile head concrete in structural use. The broken pile heads were collected from various sources of newly constructed structures and crushed to a suitable aggregate size with a mechanical crasher. Laboratory tests were conducted on both recycled and virgin aggregate. The test results revealed that aggregate gradation, aggregate crushing value, ten percent fine value, abrasion, rodded unit weight, flakiness index, elongation, wash passing, water absorption, clay lumps and friable particles, soundness, and soft fragments were all within acceptable limits. These coarse aggregates were used in the design of C 15 and C 25 class concrete. Eighteen set cylindrical molds from the concrete mix design were taken. At 7, 14, and 28 days, the compressive strengths (MPa) of concrete molds were tested. The C 15 class concrete strength was found to be 19.6, 22.9, and 24.8 with virgin aggregate and 18.1, 21.2, and 22.6 with recycled concrete aggregate, respectively. Similarly, C 25 concrete strength was found to be 28.2, 33.2, and 35.05 with virgin aggregate, whereas 25.9, 30.9, and 32.2 with recycled concrete aggregate. These findings indicate that broken pile head recycled concrete aggregate could be used as a substitute material for virgin aggregate, reducing the need for virgin aggregates.

Introduction

Concrete is the main ingredient and most commonly used material for the rapidly growing construction sector in Bangladesh. The primary components of concrete are gravel or stone, sand, water, and cement. Concrete consumption worldwide is estimated to be 2.5 tons per capita per year, which equates to 17.5 billion tons for the world's 7 billion people. This massive amount of concrete requires cement (2.62 billion tons), aggregate (13.12 billion tons), and water (1.75 billion tons) [1]. Aggregates are mined by cutting mountains or breaking river gravel or boulders. Recycled concrete can be used in new construction, saving a significant amount of natural resources. In addition to saving natural resources, recycling demolished concrete will provide other benefits, such as the creation of new business opportunities and lower disposal costs. It also saves money for the local government and other purchasers and assists in meeting its goal of reducing disposal. To improve sustainability, the use of recycled concrete aggregate in the construction sector has increased globally. It is primarily used as a substitute material to reduce the amount of virgin concrete aggregate required. Many urban areas are experiencing a critical shortage of natural aggregate for concrete production as a result of high aggregate consumption. A solution to these problems could be the recycling of construction and demolition waste, generating recycled aggregates and using them in the construction sector itself as an alternative material. It is now widely acknowledged that there is a significant opportunity for reclaiming and recycling demolished debris for use in value added applications in order to maximize economic and environmental benefits.

Natural aggregate (stone) is found in a few places in Bangladesh. Stone aggregate is the raw material for bridge construction. An old bridge is being demolished to make way for a new one, resulting in a large amount of waste concrete aggregate. Much research has recently been published on it, and studies have revealed that it has good quality as a virgin stone aggregate. Furthermore, a few studies on recycled concrete aggregate concrete have been conducted, such as permeability, shrinkage, and other deformation related properties [2].

The objectives are as follows:

a. To evaluate the physical properties of concrete such as gradation and density using recycled broken pile head aggregate concrete (RBPHAC) and virgin stone aggregate concrete (VSAC).

b. To determine the properties such as compressive strength, permeability, shrinkage, Modulus of elasticity and Poisson’s ratio using VSAC and RBPHAC.

c. To compare these properties between concrete of different aggregates and examine the feasibility of using recycled stone as coarse aggregate from these perspectives.

d. To reduce the impact of waste materials on the environment.

Literature Review

The amount of concrete demolished each year in Europe and the United States is approximately 50 60 million tons. In highway construction, demolished concrete is never used as a stabilized base or sub base. It's being used as fill. It is now time to seriously consider reusing demolished concrete in our country for the production of recycled concrete [3]. Recycled concrete can be used to construct pavements, but it has some limitations when used in structures. A comprehensive research study is underway to address these limitations and advocate for the safe and cost effective use of recycled concrete in the future. The US currently consumes 2.7 billion metric tons of aggregate per year, and road construction and maintenance work consumes another 20 30% of that amount. Pavements consume 10-15% of aggregates, and structural concrete uses the majority 60 70% of aggregate for roads and other infrastructure projects [4]. In this regard, the demand for reuse and recycling of material waste has grown over time as a result of numerous infrastructure developments brought about by rapid population growth and urbanization. Landfills are nearing capacity, with many scheduled to close in the coming years. Developing new facilities for disposal or recycling is highly contentious, putting current challenges involving waste exporting and importing organizations on the front burner. Some environmental protection measures have led to the promotion of recycling of these materials at the end of their service life [5]. A significant amount of construction materials is wasted due to improper handling at construction sites. Malaysia has limited innovative disposable facilities, as the country has limited recycling facilities. To reduce the amount of waste generated on site, coordination among all stakeholders involved in the planning, design, and construction processes is essential [6]. The volume of demolished concrete in Bangladesh is increasing due to the deterioration of concrete structures as well as the replacement of many low-rise buildings. If demolished concrete is reused for new construction, the disposal problem is solved and the demand for new aggregates is reduced. It was also discovered at some project sites that a portion of the demolished concrete was used as aggregate in foundation works with no research on the recycled aggregates [1].

Methodology

Study Area

The five separate places of the Dhaka – Khulna (N8) Expressway Project—Teghoria Trumpet Interchange, Jurain Railway Over Bridge, Abdullahpur Flyover, Kuchiamora Railway Over Bridge, and Baghor Bridge broken pile head, the sources of the broken pile heads.

Raw Materials Collection

-

Cement:

Cement is an important component of concrete. It is a fine grey powder that hardens over time due to hydration reactions and is used as a binding material in concrete mixes. Ordinary Portland Cement (OPC) is used in the study because it is of high quality and is used in the majority of construction projects in Bangladesh.

-

Water:

Water is a key ingredient in concrete. The study used tap water in the concrete mixes, which is safe to drink and free of oil and other organic impurities.

-

Fine Aggregate:

The best quality coarse sand (brown in color) known locally as "Sylhet sand" is used. This material is sieve analyzed following ASTM C136. The analysis revealed that this material is well graded and has a fineness modulus (FM) above around 2.5.

-

Coarse Aggregate:

The pile head was collected and crushed to a suitable aggregate size using an automatic crusher machine. It was the process of obtaining recycled concrete aggregate. And the fresh coarse aggregate source was Pakur Stone, India.

-

Admixture:

Chamito Plast 1220 admixture was chosen for both fresh and broken pile head aggregate concrete mix designs.

Coarse Aggregate Laboratory Test Procedures

The flow chart Figure 1 depicts the broken pile head course aggregate materials processing and preparation of concrete mix design. In Figure 2, the processing of virgin rough aggregate materials and the preparation of concrete mix design is shown.

Coarse Aggregate Preparation

Gradation Test

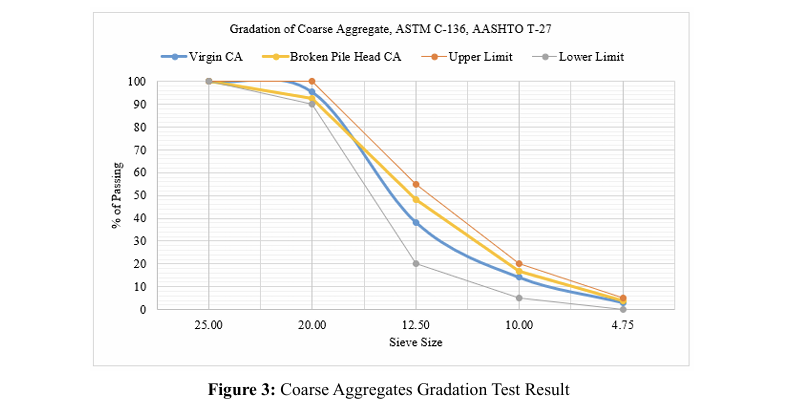

Fresh and broken pile head aggregate samples have been graded. Both aggregates were found to be well graded, and the individual sieve passing value indicated that the broken aggregate was finer than the fresh aggregate. Figure. 3 is the analysis of two coarse aggregate gradation.

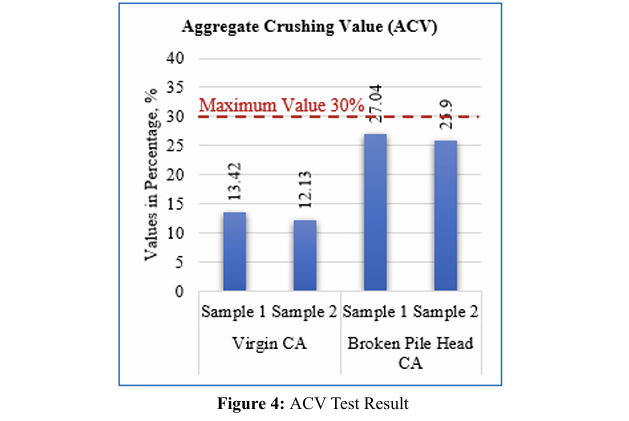

Aggregate Crushing Value

The aggregate crushing value of fresh and broken pile head aggregate samples was tested. Both aggregate values were found within the limit. It was seen that broken pile head aggregate has a higher crushing value than fresh aggregate. The primary observation on this material is that the higher amount of loss is because the recycles aggregates are coated with finer particles (concrete). Figure 4 is the graphical presentation.

Ten Percent Fine Value

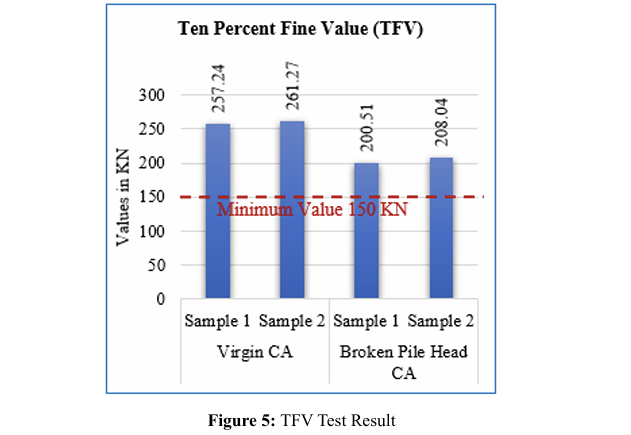

The aggregate ten percent fine value of fresh and broken pile head aggregate samples was tested. Both aggregate values were found within the limit. Fresh aggregate was found to have a higher ten percent fine value than broken pile head aggregate. Figure 5 is the graphical presentation.

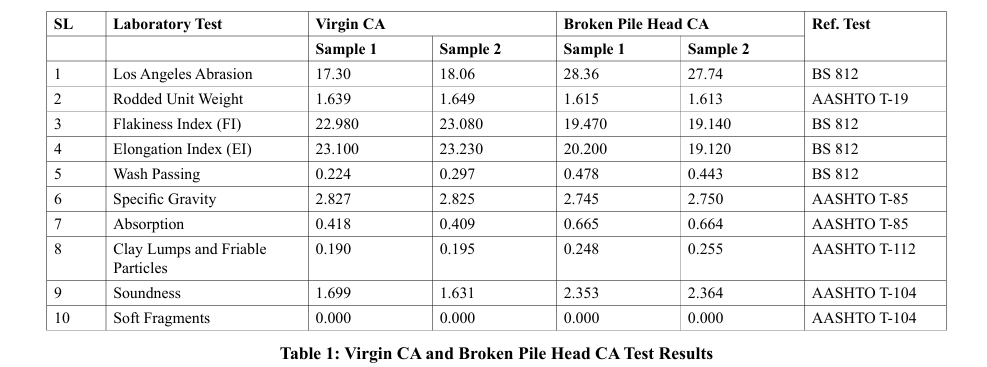

Other Tests

The Virgin CA and Broken Pile Head CA; others comparative test results were presented in the Table 1. From table it is seen that virgin coarse aggregate samples test results are better than broken pile head coarse aggregate. However, both aggregates values are within limit.

Concrete Mix Design

The concrete mixes were blended separately using virgin coarse aggregate and broken pile head coarse aggregate. It took 9 cylinders to determine concrete compressive strength, 3 for 7 days, 3 for 14 days, and 3 for 28 days. Cylindrical samples were water cured. The concrete mix proportions are given below.

Mix Proportion C15 Class Concrete

Mix proportion by weight (kg) in SSD condition (Cement: Fine Aggregate: Coarse Aggregate (virgin CA) = 290: 968: 1031.3). The mix ratio (Cement: Fine Aggregate: Coarse Aggregate = 1: 3.34: 3.56). W/C ratio 0.50. Otherwise, mix proportion by weight (kg) in SSD condition (Cement: Fine Aggregate: Coarse Aggregate (broken pile head CA) = 290: 866: 1070). The mix ratio (Cement: Fine Aggregate: Coarse Aggregate = 1: 2.98: 3.69). W/C ratio 0.50.

Mix Proportion C25 Class Concrete

Mix proportion by weight (kg) in SSD condition (Cement: Fine Aggregate: Coarse Aggregate (virgin CA) = 370: 894.4: 1047.7). The mix ratio (Cement: Fine Aggregate: Coarse Aggregate = 1: 2.42: 2.83). W/C ratio 0.38. Otherwise, mix proportion by weight (kg) in SSD condition (Cement: Fine Aggregate: Coarse Aggregate (broken pile head CA) = 370: 791.65: 1085.96). The mix ratio (Cement: Fine Aggregate: Coarse Aggregate = 1: 2.14: 2.94). W/C ratio 0.38.

Compressive Strength Test Result and Discussion

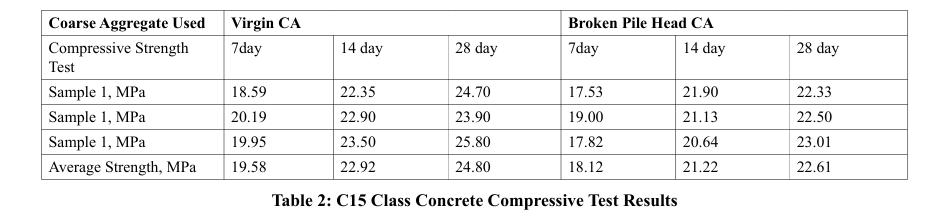

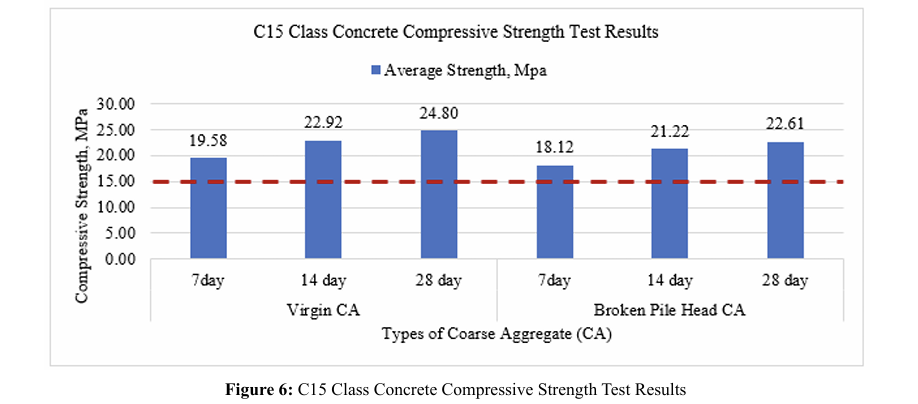

C15 Class Concrete

The samples detailed compressive strength test results are given in Table 2. All the samples test results are acceptable.

Figure 6 depicts the average value of concrete samples. It has been observed that the strength increasing rate of Virgin CA used concrete is greater than that of Broken Pile Head CA used concrete.

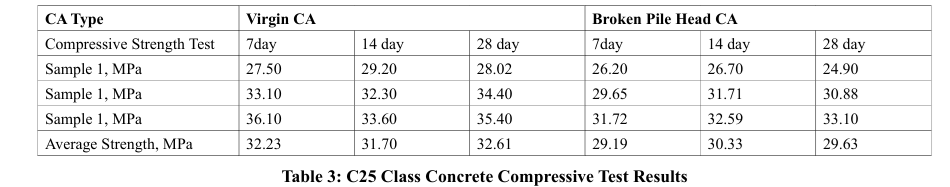

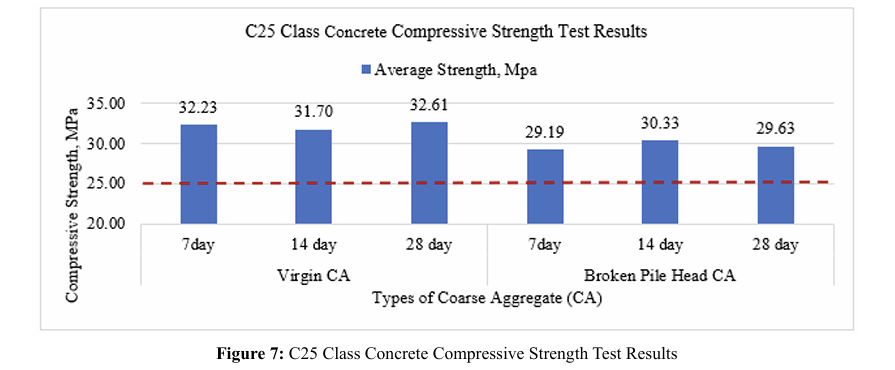

C25 Class Concrete

The samples detailed compressive strength test results are given in Table 3. All the samples test results are acceptable.

Figure 7 depicts the average value of concrete samples. It has been observed that the strength increasing rate of Virgin CA used concrete is greater than that of Broken Pile Head CA used concrete.

Conclusions

The study found that Virgin CA and Broken Pile Head CA materials have comparable properties within an acceptable range. The concrete made from these two coarse aggregate materials has a noticeably similar strength. Despite this, Virgin CA has higher quality than others, and is considered superior to all other materials.

Recommendations

The use of recycled concrete aggregate in structural work in developing countries such as Bangladesh will benefit the national economy. It saves money because it doesn't have to be mined, it has a lower environmental impact, it appeals to governments and customers, and it preserves natural resources like gravel, water, coal, oil, and it also saves landfill space.

Acknowledgments

We are immensely grateful to Moazzem Hossain Khan, Senior Material & Quality Control Engineer, N8 Expressway, Construction Supervision Consultant (CSC) for his comments on an earlier version of the manuscript, although any errors are our own and should not tarnish the reputations of these esteemed persons.

References

1. Tafsirojjaman, K. M. Taha and M. H. Haque, "A Study on Recycled Coarse Aggregate as a Partial or Full Replacement of Coarse Aggregate in Concrete Production using Fine Aggregate of FM 1.23," in 4thInternational Conference on Solid Waste Management in the Developing Countries, Khulna, Bangladesh, 2015.

2. Akhtaruzzaman, A. A., & Hasnat, A. (1983). Properties of concrete using crushed brick as aggregate. Concrete International, 5(2), 58-63.

3. Husain, A., & Assas, M. M. (2013). Utilization of demolished concrete waste for new construction. World Academy of Science, Engineering and Technology, 73(2013), 605-610.

4. Khater, H. M. (2006). Utilization of construction and demolition wastes for the production of building units. Master Theses, Zagazig University, Zagazig, Egypt.

5. Umar, U. A., Shafiq, N., Malakahmad, A., Nuruddin, M. F., Khamidi, M. F., & Salihi, I. U. (2016). Impact of construction waste minimization at construction site: case study. Jurnal Teknologi, 78(5-3), 33-40.

6. Umar, U. A., Shafiq, N., Malakahmad, A., Nuruddin, M. F., & Khamidi, M. F. (2017). A review on adoption of novel techniques in construction waste management and policy. Journal of Material Cycles and Waste Management, 19, 1361-1373.

Copyright: © 2025 This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.