Research Article - (2025) Volume 2, Issue 1

Effect of Water-Cement Ratio on the Properties of Brick Aggrigate Concrete

2Professor, Department of Civil Engineering, DUET, Bangladesh

Received Date: Jan 20, 2025 / Accepted Date: Mar 10, 2025 / Published Date: Mar 28, 2025

Abstract

Brick aggregate is widely used in concrete mixes for building construction in Bangladesh. The principal aim of this research is to study the effect of water-cement ratio on the properties of brick aggregate concrete. Two types of mix ratios along with variations in water-cement ratios have been considered in this study. The mix ratios (by volume) considered are 1:2:4 and 1:1.5:3 and the water-cement ratios (by weight) are 0.4, 0.5, 0.6 and 0.7. Emphasis is given on studying the basic properties of hardened concrete such as compressive strength, modulus of elasticity and splitting tensile strength. The properties of concrete have been determined according to the ASTM specifications. Attempts have been made to find relation between the properties of concrete and the water-cement ratio. Test results have shown that the compressive strength, splitting tensile strength and modulus of elasticity of brick aggregate concrete decrease with the increase of water-cement ratio. Within the range of water-cement ratio, the rate on both strength and stiffness of concrete is found to be higher for concrete with higher cement content. The strength and stiffness of brick aggregate concrete are higher for concrete with higher cement content up to the water-cement ratio of about 0.55 and beyond this point the trend is reversed. The rate of reduction of the strength of concrete increases with the increase of water content in excess of the hydration demand of cement up to water-cement ratio of about 0.6 and beyond this point the rate decreases.

Introduction

The effect of water content in concrete on concrete properties has been a major concern from the beginning of its use. The effect of water-cement ratio on concrete in Bangladesh, where brick is widely used as coarse aggregate, requires more analysis and investigation, despite the fact that brick aggregate has higher absorption capacity. A literature review of previous studies on the effect of water-cement ratio on concrete is presented. Rashid et al. conducted the study to investigate the properties of higher strength concrete made with crushed brick as coarse aggregate in that study, they dealt with manually crushed, well-burned, handmade bricks that are commonly available in Bangladesh [1]. The study was limited to four mix ratios and four water-cement ratios. To achieve a lower water-cement ratio, they used 19mm (0.75 inch) of brick aggregate and admixture. Singh investigated the properties of high-strength brick aggregate concrete [2]. The researcher discovered that as the water-cement ratio increases, so does the compressive strength, and that the rate of reduction is faster with a lower water-cement ratio [3,4].

We attempt to find their test outputs, despite the fact that they have some limitations, as detailed below.

• Rashid et al., studies did not specify for which mix ratio the equation is valid.

• Admixture was used for lower water-cement ratios but not for higher water-cement ratios, which could be due to a difference in workability and thus compaction.

• Abrams did not specify the upper limit of his equation's validity, and he did not link compressive strength to air content in concrete [5].

Materials and Methods

Casting of Specimens

The properties of hardened concrete are affected not only by the properties of the ingredient materials but also by the casting procedure and curing. For the sake of experimentation, we attempted to repeat this sequence of mixing, compaction, and curing. The following is the casting procedure.

Batching and Mixing

The process of measuring the quantity of different ingredients in concrete is known as batching. In this study, a cylinder was used to determine the volumetric properties of all of the concrete ingredients except water. A tilting type concrete mixture machine is used to mix concrete in this study. The coarse aggregate and some of the mixing water were added prior to starting the rotation of the mixing machine. The shape and design of the vanes fixed inside the drum determines the efficiency of the mixing operation. The mixing process should be continued after loading the mixer machine until a thoroughly and properly mixed concrete is obtained. At the end of the mixing process, the concrete should be uniform color and consistency.

Placing and Compacting

Concrete compaction is the process of removing entrapped air from concrete. Air is likely to become trapped in the concrete during the placement and mixing process. The mold and cylinder were placed on a flat, vibration-free surface. The concrete was poured into the molds using a blunted trowel. To ensure proper consolidation, a 5/8-inch diameter rod was used to tamp the concrete in the mold, with three layers and 25 blows in each layer.

Concrete Curing

Curing is the process of keeping concrete moist enough to allow cement hydration to continue. The cylinders were kept at room temperature for 24 hours after casting before being released from the mold. Curing is required to continue the hydration process. The final strength is heavily influenced by the initial moisture and temperature conditions. Immersion of specimens in water is the best method of concrete curing because it meets all curing requirements, including hydration promotion, shrinkage elimination, and heat absorption during hydration. The specimen in this study was immersed in water for 28 days.

Testing of Specimens

*Compressive Strength of Concrete

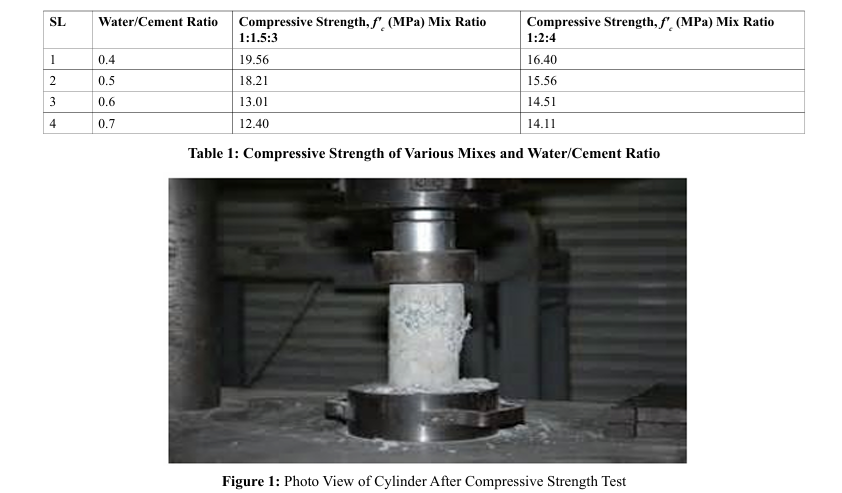

The compressive strength test is the most commonly used on hardened concrete. Concrete compressive strength test specimens come in two varieties: cubs and cylinders. This study focuses solely on the cylinder test, not the cube test. This test method determines the compressive strength of cylindrical concrete specimens such as molded cylinders. It is only applicable to concrete with a unit weight greater than 50 lb./cft. This test method involves applying a compressive axial load to molded cylinders at a rate that is within a specified range until failure occurs. The specimen's compressive strength is calculated by dividing the maximum load achieved during the test by its cross-sectional area. Loading should be applied in a continuous manner. When the machine is idle, the moving head should move at a rate of approximately 0.05 in/ min. This test method meets the ASTM standard specification C39/C39M-99 requirements [6]. Table 1 shows the compressive strength test results.

Splitting Tensile Strength

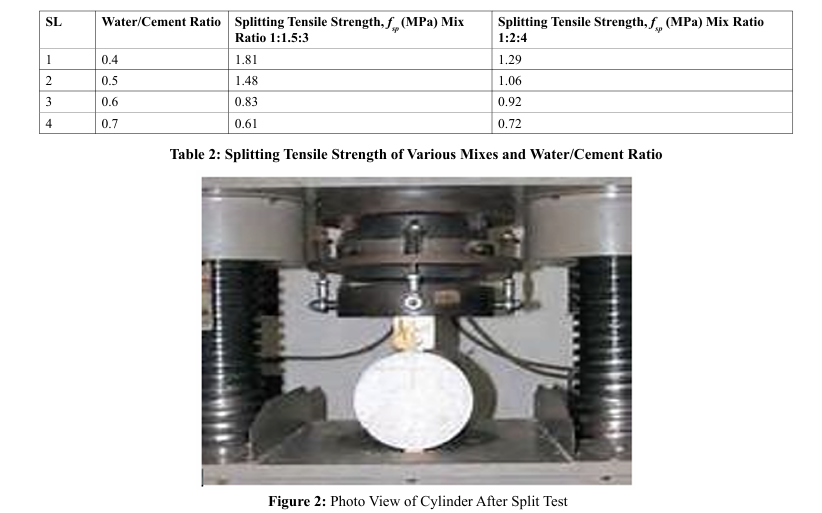

This test method determines the splitting tensile strength of a cylindrical concrete specimen. Splitting tensile strength is used to assess the shear resistance provided by reinforced lightweight concrete members. The test consists of applying compressive line load along the opposite generators of a concrete cylinder placed with its axis horizontal between platens. The magnitude of split cylinder strength is given by "f" _"sp" "=" "2P" /"πdl". In this test, 24-cylinder specimens with various mix ratios and water-cement ratios were tested. The ASTM specifications C 496-96 were used to determine the splitting tensile strength of cylindrical concrete [7]. Table 2 shows the test results.

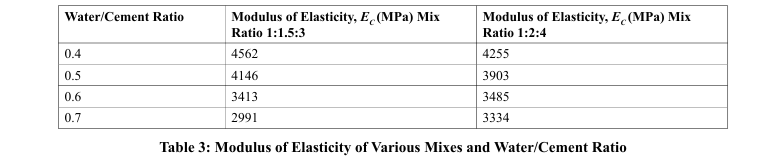

Concrete Modulus of Elasticity The modulus of elasticity is calculated by subjecting a cylinder specimen to uniaxial compressive stress and measuring the deformation with a dial gauge fixed between certain gauge lengths. The strain is calculated by dividing the dial gauge reading by the gauge length, and the stress is calculated by dividing the load applied by the area of cross section. The stress-strain relationship is established after a series of readings. Young's modulus of elasticity can only be applied to the straight portion of the stress-strain curve. Because no part of the graph in concrete is straight, the modulus of elasticity is calculated using the tangent drawn to the curve at the origin. This test method complies with the ASTM standard specifications C 469-94 [8]. According to the ASTM standard, EC is calculated on the basis of 40% compressive strength. Concrete modulus of elasticity = (40% of ultimate concrete compressive strength/corresponding strain) Table 3, displays the modulus of elasticity of several specimens obtained from the experimental investigation.

Results and Discussions

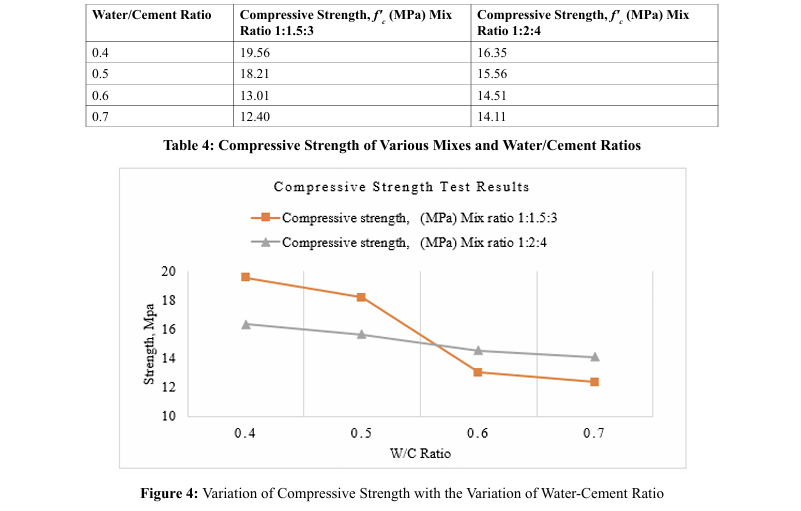

Comparison of Compressive Strength

The above table shows that the compressive strength of concrete decreases as the water-cement ratio increases. It is obvious that the strength of concrete is primarily determined by the strength of cement paste, and the strength of cement paste increases with cement content and decreases with air content. Figure 4, depicts the variation in compressive strength of brick aggregate concrete with variation in water-cement ratio and relative strength reduction.

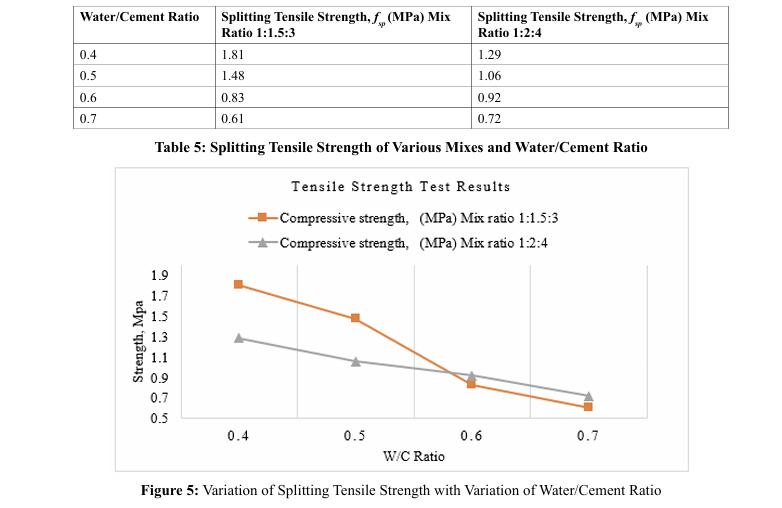

Comparison of Tensile Strength The splitting tensile strength of brick aggregate concrete decreases with increasing water-cement ratio for all mixes, as the tensile strength of concrete is dependent on emptied pores left by water mixed during specimen preparation, as shown in Figure 5. Although water is increased with higher cement-content concrete, the splitting tensile strength is higher than that of lower cement-content concrete up to a water/cement ratio of about 0.6. This is because the bonding strength between aggregate surfaces and cement paste is also dependent on the cement quantity. The higher the cement content, the higher the tensile strength up to a water-cement ratio of around 0.60. Beyond this point, concrete with higher cement has lower tensile strength than concrete with lower cement because excessive segregation with rich mix leaves more pores and non-uniform coating around aggregate particles, resulting in lower tensile strength. The rate of reduction of strength of concrete made with rich mix is also seen in Figure 5 up to water/ cement ratio of 0.60, after which the trend reverses.

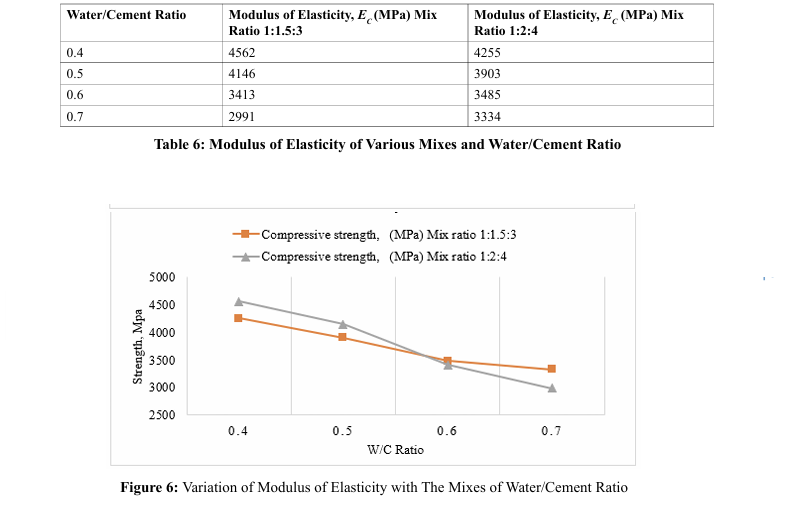

Comparison of Modulus of Elasticity The modulus of elasticity is determined by the strength and porosity of the concrete. According to Figure 6, the modulus of elasticity of concrete made with mix ratio 1:1.5:3 up to a water cement ratio of around 0.60 is higher than that of concrete made with mix ratio 1:2:4 because excess water content leaves more pores, resulting in more deflection, but the compaction level and strength of cement paste cause concrete to have a higher modulus of elasticity with the mix ratio 1:1.5:3. Beyond this water-cement ratio, concrete segregates and leaves more pores in hardened concrete as water content increases, as it does in a rich mix, and thus the modulus of elasticity of concrete made with the mix ratio of 1:1.5:3 is greater than that of concrete made with the mix ratio of 1:2:4. Because of the well compaction level, the reduction of modulus of elasticity of concrete made with a ratio of 1:1.5:3 is lower than that of concrete made with a ratio of 1:2:4. As the amount of water-cement increases, so does the rate of reduction.

Conclusion

The compressive strength, splitting tensile strength, and modulus of elasticity of brick aggregate concrete are higher for concrete with higher cement content up to a water-cement ratio of about 0.55, after which the trend reverses. The rate of reduction of compressive strength, splitting tensile strength, and modulus of elasticity of brick aggregate concrete with higher cement content is much higher than that of concrete with lower cement content up to a water-cement ratio of about 0.6. The rate of reduction of strength properties of brick aggregate concrete is not significant above the water-cement ratio of 0.6 for concrete with higher cement content. It is recommended that the physical and chemical properties of brick aggregate concrete made with different mix ratios be thoroughly investigated. The effect of the water-cement ratio on air entrainment of brick aggregate concrete could be studied. Other properties of brick aggregate concrete, such as thaw durability and fatigue strength, may be investigated. More water-cement ratios with short intervals such as 0.40, 0.45, 0.50, 0.55, 0.60, 0.65, and 0.70 may be used to investigate the effect of the water-cement ratio on concrete properties.

Acknowledgments

We would like to express our gratitude to the Department of Civil Engineering, DUET; laboratory technician for assisting us in obtaining the resources we required to conduct the laboratory investigation.

References

- Rashid, M. A., Hossain, T., & Islam, M. A. (2009). Properties of higher strength concrete made with crushed brick as coarse aggregate. Journal of Civil Engineering (IEB), 37(1), 43-52.

- Singh, B. G. (1958, April). Specific surface of aggregates related to compressive and flexural strength of concrete. In Journal Proceedings (Vol. 54, No. 4, pp. 897-907).

- Abd Elaty, M. A. A. (2014). Compressive strength prediction of Portland cement concrete with age using a new model. HBRC journal, 10(2), 145-155.

- Influence of Age on Compressive Strength of Ordinary Portland Cement Concrete at Different Water-Cement Ratios, Concrete Society Technical Report No: 29, 1986.

- Brief Description of Water Cement Ratio and Abrams' law, Civil Daily Info, 2017. [Online]. [Accessed 22 August 2022].

- ASTM C39/C39M-99, Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens, in American Society of the International Association for Testing and Materials, United States, 1999.

- ASTM C496-96, Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens, in American Society of the International Association for Testing and Materials, United States, 1996.

- ASTM C469-94, Standard Test Method for Static Modulus of Elasticity and Poisson's Ratio of Concrete in Compression, in American Society of the International Association for Testing and Materials, United States, 1994.

Copyright: © 2025 This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.